Thoroughly. Cost-saving. Environmentally friendly.

Industrial cleaning

Parts cleaning

Pre- and post-treatment

Industrial cleaning

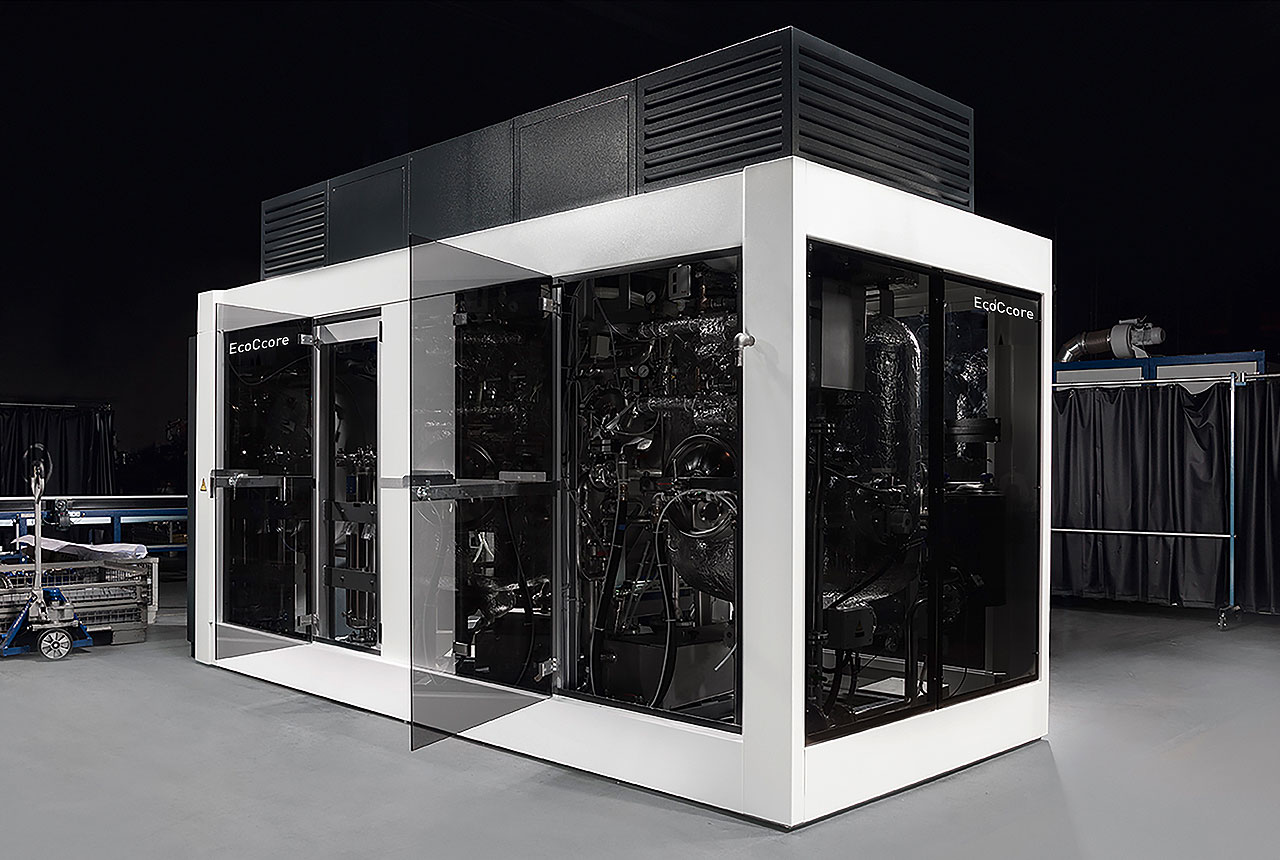

Our vacuum-assisted Dürr / Ecoclean EcoCcore cleaning system has basket dimensions of 670x480x400. This corresponds to the “Schäfer 1” industry standard.

Two tanks enable pre-cleaning and main cleaning in the shortest possible time.

Modified alcohol removes oils, fats, salts, (metallic) particles and similar impurities from your parts in an environmentally friendly way without chemically altering the surface.

Thanks to swivel and turning technology, even complex parts can be reliably cleaned of dirt with this rotary flooding system.

The cleaning processes:

- Steam pre-degreasing

- Splashing

- Ultrasonic flooding or injection pressure flooding

- Flushing

- Steam degreasing (fine cleaning with pure alcohol steam for maximum cleanliness)

can be individually combined, depending on the type of contamination and component-specific requirements.

The bipolar cleaning medium used is recycled by physically optimized separate filter and distillation systems. This technology without waste water and without exhaust air- ensures that your parts are cleaned in an energy-efficient and environmentally friendly manner. At the same time, they are perfectly prepared for subsequent processes such as final assembly, welding and gluing.

Environmentally friendly and cost-effective – simply a clean thing!