Holder Oberflächentechnik GmbH invests in sustainable coating with electrodeposited zinc-nickel in cooperation with Coventya GmbH.

Latest news

A new cascade process for cleaning aluminium parts saves resources - about half of the necessary energy and fresh water, and about a quarter of the CO2 emissions.

As one of the first surface coaters in the world, HOLDER Oberflächentechnik GmbH will have a carbon-neutral production from 2021 on.

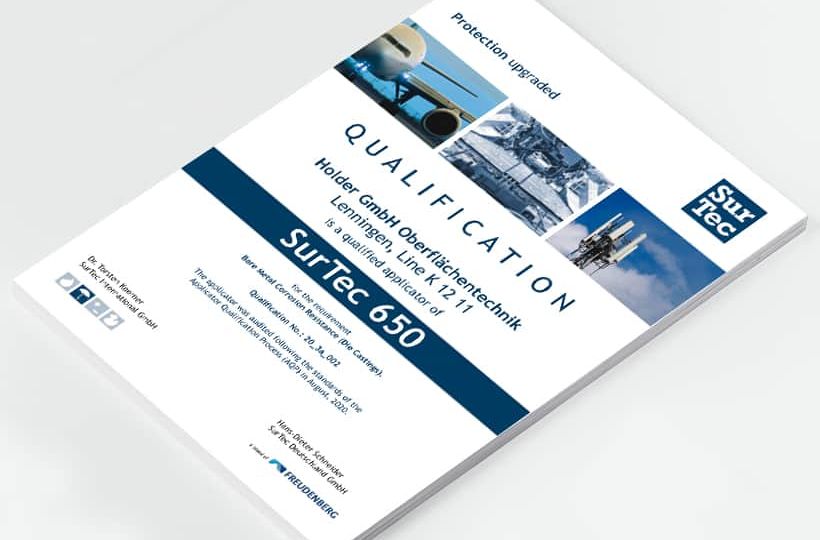

Following an intensive and successful process line audit, Jochen Holder and Christof Waibel received the certificate as "approved SurTec 650 coater" for Holder GmbH Oberflächentechnik from Dr. Torsten Koerner and Andre Quester of SurTec in September.

On Saturday, 21.09.2019, a team of 12 employees from Holder GmbH Oberflächentechnik took part in an outdoor extreme steeplechase in Metzingen. Over a distance of over 12 kilometres and 400 metres in altitude, 15 different obstacles as well as various water and mud pools had to be overcome.

From 14 to 16 January 2020, Holder GmbH Oberflächentechnik will be presenting products from the fields of heat treatment, surface technology and hardening processes as well as surface finishing at EUROGUSS 2020, Europe's largest trade fair for die casting.

On 27.03.2019 the mayor of Laichingen Klaus Kaufmann and the CDU politicians Kurt Wörner, Thomas Salzmann and Manuel Hagel were guests in our factory in Laichingen. They listened with great interest to the explanations of Managing Director Jochen Holder, who personally guided them through the spacious factory halls.

Our vacuum-assisted Dürr / Ecoclean EcoCcore cleaning system has basket dimensions of 670x480x400. This corresponds to the "Schäfer 1" industry standard.

The large-scale plant, which has been successfully in operation since 2015, has been duplicated due to the continuing increase in demand.

The company's own Holder soccer team is highly motivated and this year they took again part in the "Hartmann Indoor Soccer Cup" in Lenningen.